Productsutility generation & distribution

key features

1. Compressed Air

In the pharmaceutical sector, compressed air serves numerous roles in production and packaging processes. It’s utilized for tasks such as drying bottles before filling, conveying pills, operating pneumatic valves and cylinders, and even providing breathing air systems.

Given the diverse applications, each demands varying levels of air quality and specific combinations of air treatment. Consequently, there’s no universal standard that every process must meet due to the wide-ranging uses of compressed air within the industry.

2. Steam

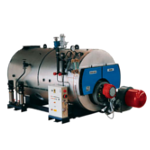

- Industrial steam, also known as Black Steam, is produced in boilers and serves as a utility. It does not come into contact with the product or process equipment. This steam contains various additives to safeguard the boilers and pipes against precipitation and corrosion.

- Pharmaceutical steam, alternatively termed pure steam or Clean Steam, is generated from treated water, specifically Purified Water. The condensation of this steam adheres to pharmacopoeia parameters, ensuring it meets the standards for Water for Injection (WFI) grade water.

3. Water

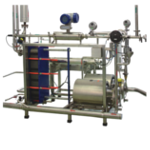

We offer comprehensive solutions and complete systems for the generation, storage, and distribution of Purified Water (PW), as well as steam sterilization, all compliant with the latest pharmacopeia standards. Our offerings encompass the entire process, starting from Pre-Treatment to Double Pass Reverse Osmosis systems, Electro Deionization systems, Water for Injection Multi-Column Distillation plants, and Pure Steam Generators (PSG).

All equipment and plants are crafted using sanitary AISI 316L Stainless Steel, featuring electro-polished tubes and fittings with a surface finish of RA 0.4 µm. The piping and fittings are meticulously welded using state-of-the-art orbital welding machines. Additionally, all other fittings and equipment, including valves, pumps, and instruments, are of sanitary type. Optionally, plants may also be equipped with PVDF piping systems.

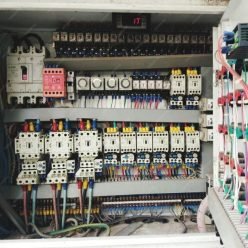

As a standard offering, all plants are skid-mounted with SS 304 stainless steel, accompanied by a stainless steel control panel and a user-friendly touch screen for simplified operation.

Clean Utility Distribution

We employ stainless steel tubing and fittings with electro-polished surfaces for clean utility distribution, ensuring minimal contamination risk and optimal performance. Zero dead-leg block valves with built-in sampling ports enable precise control and monitoring, while sanitary heat exchangers maintain process temperatures as needed.

At HVACer, we are committed to delivering reliable, efficient, and compliant utility generation and distribution solutions tailored to the unique needs of pharmaceutical and biopharmaceutical facilities. Contact us today to learn more about how we can support your project requirements.

Related products & Services

Let Us Transform Your Project Vision into Reality

At HVACer, we believe in a customer-centric approach to sales. Rather than setting sales targets for our sales team, we prioritize evaluating their performance based on customer feedback. Our sales team’s primary goal is not just to sell products but to understand your requirements thoroughly. If your requirement goes beyond our product range we are committed to referring you to world-class brands within our network because your project completion is the number one priority. So, don’t hesitate! Click below to experience the magic of our sales team as they wield their expertise to turn your dream project into reality.