CONTAINMENT TECHNOLOGY

Productscontainment technology

Effective Positive & Negative Containment Solutions for Enhanced Product, Personnel, and Environmental Safety

HVACer specializes in the design, construction, and commissioning of containment solutions tailored to handle airborne particles encountered during the handling of drug compounds in pharmaceutical, biotech, and related applications. Our experienced team is proficient in delivering proven containment solutions.

Understanding Containment Essentials

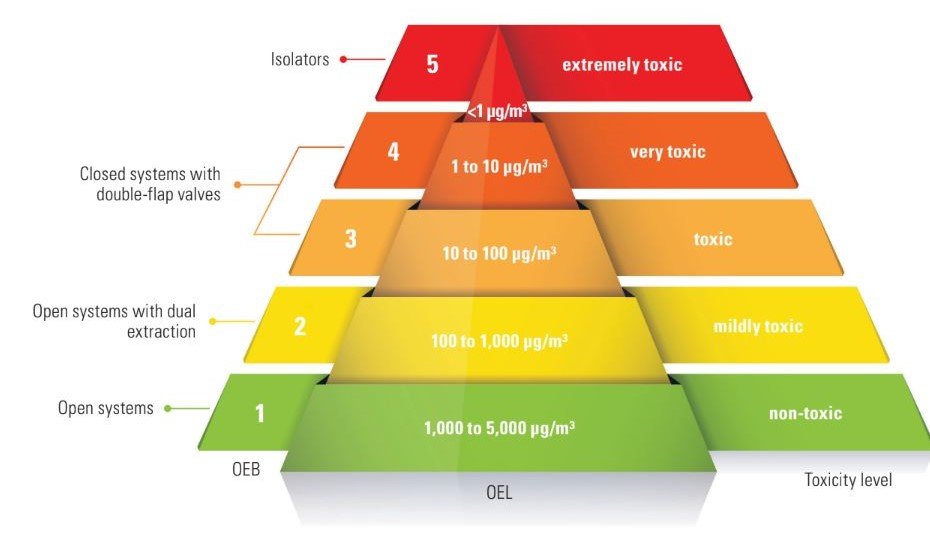

Containment has emerged as a critical aspect of modern production processes. With Active Pharmaceutical Ingredients (APIs) becoming increasingly potent, with over 50% of new chemical entities (NCEs) classified as potent (OEL <10 μg/m3), safeguarding the health and well-being of operators worldwide is paramount. Navigating the array of available hardware manufacturers and containment methods poses challenges in selecting the most suitable equipment to ensure the safety of products, personnel, and the environment.

Process Machine Integrated Solutions

HVACer offers a diverse range of containment solutions tailored to the nature of the drug and containment philosophy. From simple glove box designs to intricately integrated process systems meeting OEL 5 standards, we can accommodate customized processes such as dispensing, sampling, reactor operations, milling, sieving, blending, and granulation in both API and Formulations.

Specialized attention for High-Potency Drugs

Manufacturing oncology drugs, hormonal products, or other highly potent combinations demands specific attention to avoid operator exposure to the drug and prevent cross-contamination with other products manufactured in the same facility.

| BAND | OEB 1 | OEB 2 | OEB 3 | OEB 4 | OEB 5 | OEB 6 | OEB 7 |

|---|---|---|---|---|---|---|---|

| OEL | >1000 – 5000 µg/m3 | >100 – ≤1000 µg/m3 | >10 – ≤100 µg/m3 | >1 – ≤10 µg/mv3 | <1.0 – 0.01 µg/m3 | 0.01 – 0.001 µg/m3 | <0.001 µg/m3 – <1 ng/m3 |

| Use | Ventilation Containment | Ventilation Containment or Flowhoods without downflow (single pass Fume cabinets) | Downflow Booths or VBEs, Flowhoods | VBEs or DFBs with higher containment, Flowhoods with downflow and inflow for small volume | Isolators recommended however if handling less than 3kg and short task duration, low dust cloud potential reverse oRABs possible | Isolators | Isolators |

HVACer Features

In the pharmaceutical industry, there are two primary types of steam:

- Industrial steam, also known as Black Steam, is produced in boilers and serves as a utility. It does not come into contact with the product or process equipment. This steam contains various additives to safeguard the boilers and pipes against precipitation and corrosion.

- Pharmaceutical steam, alternatively termed pure steam or Clean Steam, is generated from treated water, specifically Purified Water. The condensation of this steam adheres to pharmacopoeia parameters, ensuring it meets the standards for Water for Injection (WFI) grade water.

Related products & Services

Let Us Transform Your Project Vision into Reality

At HVACer, we believe in a customer-centric approach to sales. Rather than setting sales targets for our sales team, we prioritize evaluating their performance based on customer feedback. Our sales team’s primary goal is not just to sell products but to understand your requirements thoroughly. If your requirement goes beyond our product range we are committed to referring you to world-class brands within our network because your project completion is the number one priority. So, don’t hesitate! Click below to experience the magic of our sales team as they wield their expertise to turn your dream project into reality.